Electric Press Brake,Servo Electric Press Brake,servo press brake

Model:3Ton/200mm, 6ton/400mm, 12ton/600, 18ton/800, 20ton/1200, 30ton/1200,40ton/1300mm

Servo Electric Press Brake widely used in sheet metal industry opens a new trend of all electric servo drive replacing hydraulic main drive. The tonnage and output of all-electric press brake are increasing.

Advantage:

Servo Drive-Technology Provides High Precision Bending Results

100% Pure electric power, with no oil.

Up to 50% less energy consumption compared to a hydraulic press brake.

Up to 35% faster compared to a hydraulic press brake.

High efficiency and precision.

High bending speed and less noise.

Full bending length between side frames.

Less maintenance cost.

Eco friendly.

Friendly user interface.

Electric Press Brake Machine Parameter and Model

Model

Parameters |

Pressure

capacity

(KN) |

Working table length

mm |

Bending stroke

mm |

Back gauge stroke

mm |

Axis No. |

Main shaft power

KW |

Quick down

return speed

mm/s |

Working speed |

Opening height |

Throat depth |

Distance between upright |

| ECO-12/600 |

120 |

600 |

120 |

150 |

3 |

5.5 |

200 |

<30 |

420 |

150 |

520 |

| ECO-20/1000 |

200 |

1050 |

120 |

300 |

4 |

11 |

200 |

<30 |

430 |

250 |

930 |

| ECO-30/1200 |

300 |

1250 |

150 |

500 |

4 |

13 |

300 |

<30 |

470 |

250 |

1150 |

| ECO-35/1200 |

350 |

1250 |

150 |

500 |

6 |

13 |

200 |

<20 |

470 |

250 |

1150 |

| ECO-40/1300 |

400 |

1300 |

150 |

500 |

6 |

15 |

200 |

<20 |

470 |

300 |

1200 |

| ECO-40/1600 |

400 |

1600 |

150 |

500 |

6 |

15 |

200 |

<20 |

470 |

300 |

1400 |

| ECO-50/2000 |

500 |

2000 |

150 |

500 |

7 |

30 |

250 |

<20 |

530 |

350 |

1400 |

| ECO-60/2500 |

600 |

2500 |

150 |

500 |

7 |

30 |

200 |

<20 |

530 |

350 |

2300 |

I. Machine model, name and quantity

I. Machine model, name and quantity

1. Model: ECO-12Ton/600

2. Name: full-electric servo CNC bending machine

3. Quantity: 1 set

II. Machine main technical parameters

| NO. |

Name |

Unit |

Parameter |

Remark |

| 1 |

Nominal pressure |

T |

12 |

|

| 2 |

Working table |

mm |

600 |

|

| 3 |

Distance between housings |

mm |

450 |

|

| 4 |

Throat depth |

mm |

200 |

|

| 5 |

Sliding stroke |

mm |

120 |

|

| 6 |

Max.opening height |

mm |

420 |

|

| 7 |

Back gauge stroke |

mm |

200 |

|

8 |

Slide running speed |

Empty loading |

mm/s |

200 |

|

| Working |

mm/s |

1-30 |

|

| Return |

mm/s |

200 |

|

9 |

Main motor |

Power |

KW |

5.5 |

|

| Quantity |

set |

1 |

|

| 10 |

Control system |

Model |

|

ECO-10ES |

|

| Axes number |

|

2 |

|

| 11 |

Dimension |

L |

mm |

750 |

|

| W |

mm |

750 |

|

| H |

mm |

1980 |

|

| 12 |

Machine weight |

Kg |

760 |

|

III. Main configurations list

III. Main configurations list

| NO. |

Name |

Supplier |

Remark |

| 1 |

Main motor |

SANYO,Japan |

|

| 2 |

Linear guide |

HIWIN |

|

| 3 |

Ball screw rod |

TBI |

|

| 4 |

Electrical components |

SCHNEIDER |

|

| 5 |

Bearing |

NSK,Japan |

|

| 6 |

Control system |

ECO-10ES/DELEM |

|

IV. Main technical indicators and functions

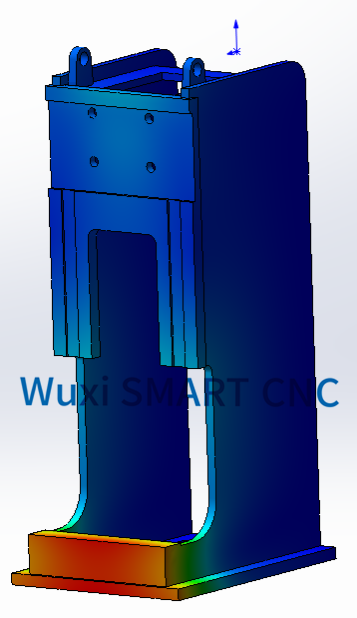

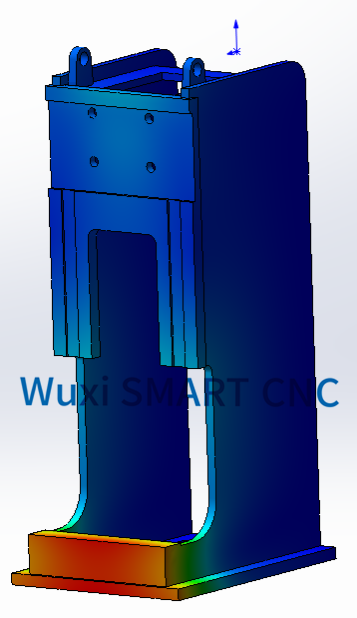

1. Finite element analysis high-rigidity design

Key mechanical components of machine tools adopt finite element analysis deformation and safety factor to ensure that the overall high rigidity requirements of the machine tool and the reliability of long-term use.

Intensity analysis Rigidity analysis

2.ECO-10ES CNC system

The ECO-10ES CNC system is mainly used in the field of full-electric servo bending machines. It is a high-end CNC system tailor-made based on market demand. It’s functional, rich in built-in resources, safe, efficient, energy-saving and green environmental protection characteristics product.

Product characteristics of CNC systems

Reliable performance

The CNC system ECO-10ES uses a high-end CNC system development platform and advanced sheet metal bending special algorithms and motion control algorithms. All the main boards adopt industrial-grade chips. CNC systems have passed EMC electromagnetic compatibility verification and high and low temperature environment adaptability testing.

High-speed and high-precision control

CNC systems adopt a high-speed increase and speed-up algorithm and trajectory forward-looking algorithm. Before bending, CNC systems are pre-planned based on the speed and vector characteristics of the bend to make overall planning on the sports trajectory. The soft movement characteristics make high-speed and high essence effectively integrate!

High speed: the maximum fast progress speed of the Y-axis is 200mm/s, and the maximum working speed is 30mm/s.

High precision: repeat positioning accuracy ± 0.01mm.

Processing consistency: avoid the effects of changes in oil temperature on bending workpieces.

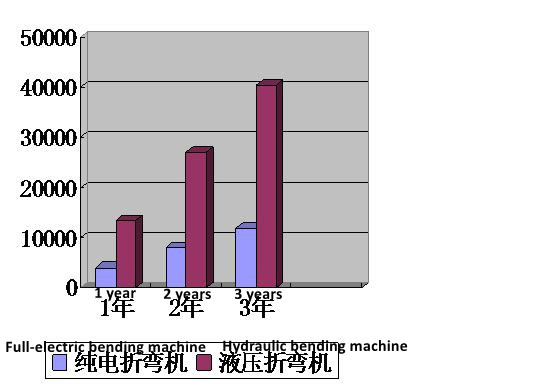

3. Energy-saving and environmental protection

CNC system ECO-10ES is mainly used in full-electric servo CNC bending machines, which saves electricity and green environmental protection.

Special power saving: the difference between the power consumption of the full -electric servo bending machine and the electric hydraulic servo bending machine is like the difference between the frequency frequency air conditioner and the ordinary air conditioner. The full-electric servo bending machine will automatically output the appropriate power electrical energy according to the working conditions, so it is particularly power-saving.

Green environmental protection: no need to use and replace hydraulic oil, which terminate the pollution of waste hydraulic oil to the environment.

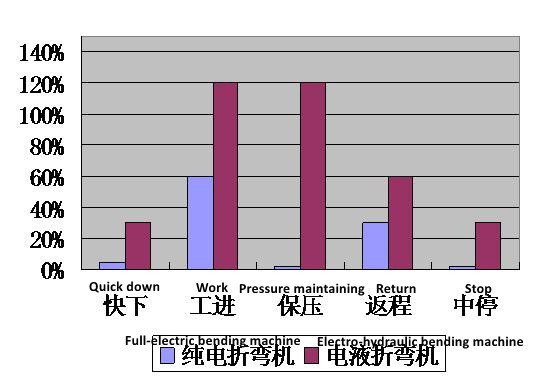

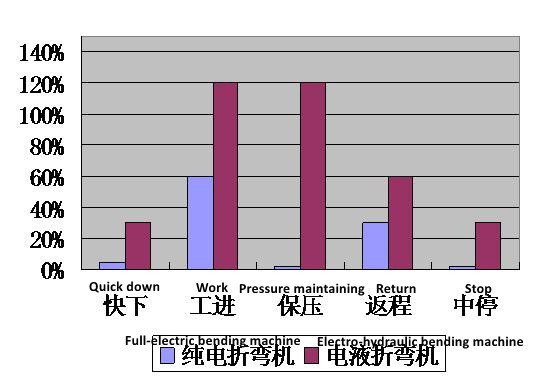

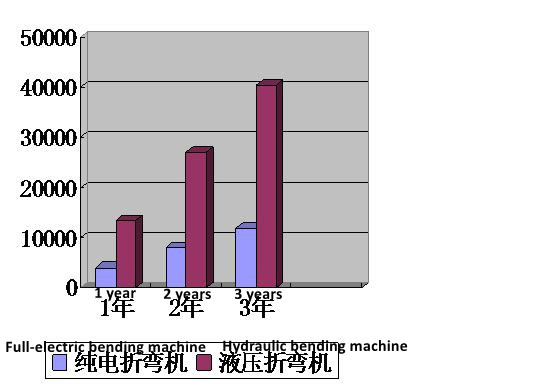

40T full-electric servo bending machine and commonly used 40T electro-hydraulic bending machine power consumption comparison:

Each working step motor power comparison

Power consumption

4. The main axle power box

The main axle power box can pass the bending pressure, using heavy roller screws and bearings, and a long life design. The sealing protection design ensures that key components are not affected by external dust.

The main axle power box/Synchronous wheel/AC servo motor

Main technical indicators and functions:

- Intelligent tools loading monitoring to ensure the safety of the tool;

- The five-line touch screen, the service life of more than 10 million times high and reliable, the operation process is simple and fast;

- The automatic calculation function of the bending pressure, exceeding the stress limit range alarm prompt;

- Calculating function of the "Direct" calculation function of the back gauge: according to the size and plastic deformation of the sheet metal, calculate the back gauge position directly according to the neutral layer;

- Arc continuous bending function;

- Mold parameter library: establish a mold parameter library for customers, so that customers can quickly call parameters for sheet metal bending.

5. Back gauge

Standard as a single axis (X) CNC back gauge, two axes (X, R), four axes (X, R, Z1, Z2), six axes (X1, X2, R1, R2 , Z1, Z2) are optional according to customers’ demands.

6. Upper mold clamps

The upper mold clamp adopts the usual fast clamping device.